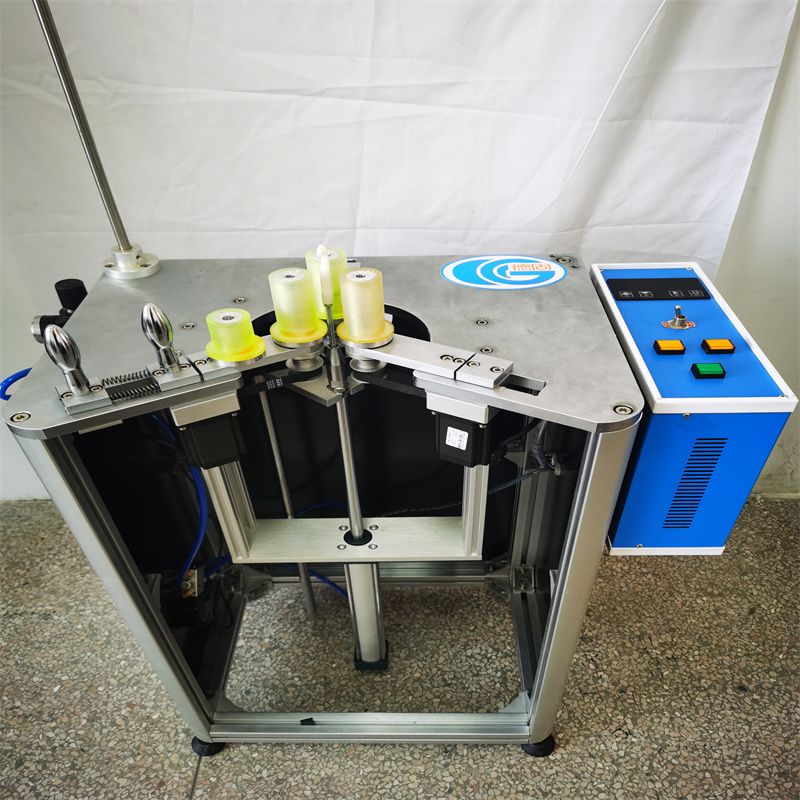

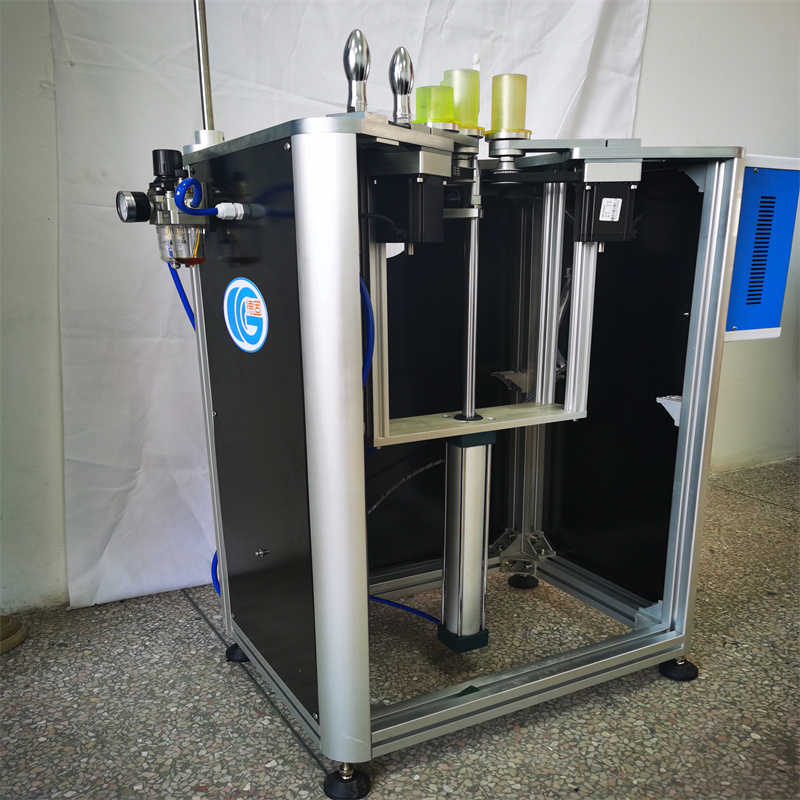

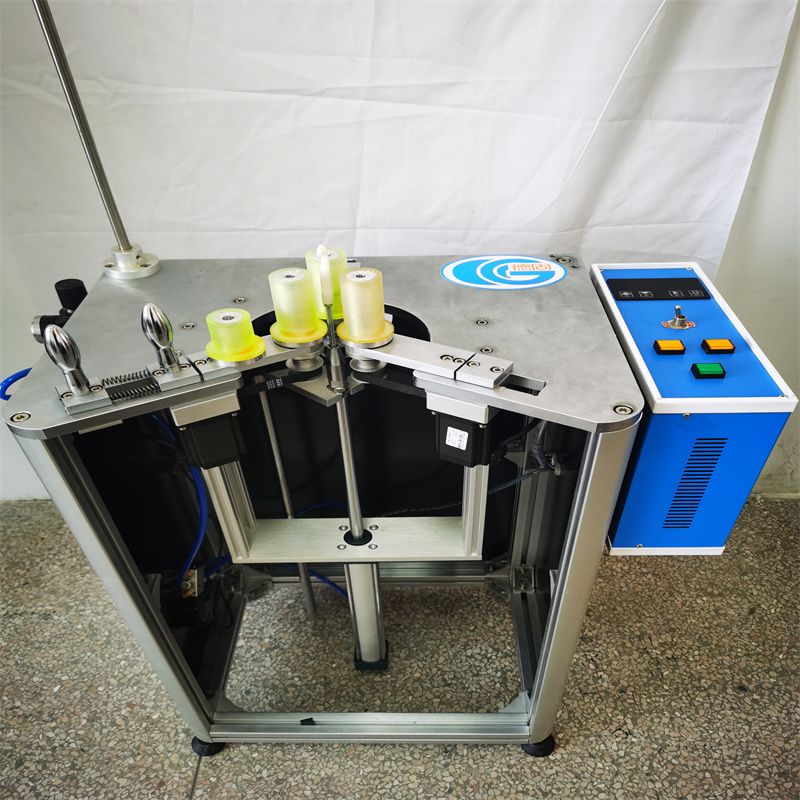

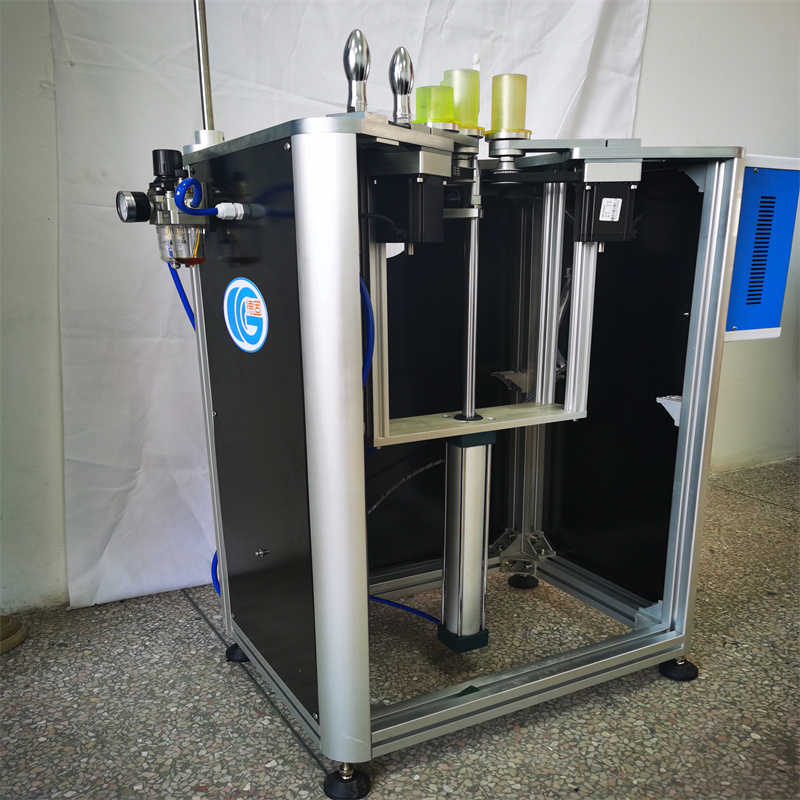

In the ever-evolving world of technology, advancements in machinery continue to push boundaries and revolutionize various industries. The latest breakthrough comes in the form of the Toroidal Core Winding Machine, a cutting-edge device designed to enhance the production of transformer coil winding. Developed by Ruff Industries, this state-of-the-art Toroidal Winding Machine promises to streamline the manufacturing process, improve efficiency, and deliver superior quality coils. In this article, we delve into the intricate details of this groundbreaking innovation, exploring its features, benefits, and potential impact on the transformer industry. 1. Understanding the Toroidal Core Winding Machine: The Toroidal Core Winding Machine is a highly specialized piece of equipment designed to wind coils onto toroidal cores. It automates the traditionally labor-intensive process, significantly reducing production time and enhancing accuracy. The machine's advanced technology ensures precise winding tension, consistent layering, and uniform distribution of the coil, resulting in enhanced performance and reliability of transformers. 2. Key Features of the Toroidal Core Winding Machine: a. High Precision: The Toroidal Core Winding Machine employs cutting-edge technology to achieve unparalleled precision in winding coils. This eliminates the risk of human error, ensuring each coil is wound with utmost accuracy. b. Versatility: The machine accommodates a wide range of toroidal core sizes, making it suitable for various transformer applications. This versatility allows manufacturers to produce coils for different voltage capacities and specifications. c. Automation: The Toroidal Core Winding Machine automates the coil winding process, reducing the need for manual labor and minimizing the risk of inconsistencies. This automation feature enhances productivity and allows manufacturers to meet growing demands efficiently. d. Speed and Efficiency: With its advanced design and automation capabilities, the machine offers exceptional speed and efficiency, enabling manufacturers to achieve higher production rates without compromising quality. e. User-Friendly Interface: The machine's intuitive interface makes it easy to operate, even for less experienced operators. Its user-friendly design allows for quick setup and adjustment, minimizing downtime and maximizing productivity. 3. Advantages of Toroidal Core Winding Machine: a. Enhanced Product Quality: The Toroidal Core Winding Machine ensures consistent and precise winding, resulting in coils with superior performance and reliability. This translates into transformers that deliver optimal power transmission and minimized losses. b. Increased Production Efficiency: By automating the winding process, the machine significantly reduces production time, allowing manufacturers to meet tight deadlines and handle larger volumes of orders. c. Cost Savings: The automation feature eliminates the need for extensive manual labor, reducing labor costs and minimizing the risk of human errors. Additionally, the machine's efficiency leads to higher productivity, maximizing return on investment. d. Adaptability: The Toroidal Core Winding Machine's ability to accommodate various toroidal core sizes makes it suitable for both small-scale and large-scale production, providing manufacturers with flexibility and scalability. 4. Impact on the Transformer Industry: The introduction of the Toroidal Core Winding Machine is expected to revolutionize the transformer industry in several ways: a. Increased Market Competitiveness: Manufacturers equipped with this advanced winding machine can offer high-quality coils at competitive prices, gaining a competitive edge in the market. b. Improved Transformer Performance: The precise winding achieved by the machine ensures optimal power transmission, reduced losses, and improved overall transformer performance. c. Meeting Growing Demand: The machine's automation capabilities and high production efficiency enable manufacturers to meet the increasing demand for transformers in sectors such as renewable energy, electric vehicles, and smart grid systems. d. Technological Advancements: The Toroidal Core Winding Machine represents a significant technological advancement in the field of transformer coil production, setting new benchmarks for future innovations. Conclusion: The Toroidal Core Winding Machine developed by Ruff Industries presents a game-changing solution for transformer coil winding. With its advanced features, automation capabilities, and exceptional precision, this innovative machine promises to revolutionize the industry, enhancing production efficiency, product quality, and market competitiveness. As the demand for transformers continues to rise, this cutting-edge technology will undoubtedly play a pivotal role in meeting industry requirements and driving further advancements in the field.